Although it is difficult to give an exact definition of a membrane, a more general definition could be: a selective barrier between two phases, the term "selective" being inherent to a membrane or a membrane process. It should be noted this is a macroscopic definition while separation should be considered at the microscopic level. To obtain a more informative understanding, membranes can simply be classified by nature into two categories: biological and synthetic membranes.

A membrane filter is a thin, polymeric film or filament made up of millions of microscopic pores. The size of these pores determines the nominal pore size rating of the membrane. Membrane filters can be used in quantitative separation or the filtration of suspended matter from liquids and gases. Membranes have many different properties that affect the performance of the filter in applications.

Often times membrane filters are classified according to their structures into several categories in terms of "pore size" (listed from smallest to the largest); namely, gas separation, dialysis/hemodialysis, reverse osmosis, ultrafiltration, and microporous membranes.

Microporous membrane is defined as a thin walled structure having an open spongy morphology of precisely controlled pore size typically ranging from 0.03 μm up to 10 μm in diameter. In terms of membrane geometry, three types of microporous membranes are commercially available: flat sheet, hollow fiber, and tubular membrane. The flat sheet geometry is the most popular and useful configuration among these three types. Microporous membrane can be further divided into unsupported and supported variants.

Microporous membranes are readily characterized with various techniques including scanning electron microscopy, bubble-point method, mercury intrusion porometry, and permeation measurements. Among these methods, the first two are commonly accepted and used in the industry due to the ease and convenience of testing procedures.

Microporous membrane has been industrialized for many years in the U.S. and Europe and found widespread use in various fields such as pharmaceuticals, electronics, beverages, chemicals, environmental, and analytical for traditional filtration, purification, clarification, cold sterilization, concentration and venting. In addition to traditional applications, microporous membrane has also been recognized in non-traditional applications attributed to its specific 3D pore structure and high surface area per unit weight uniqueness. These applications include drug-abuse tests, one-Northern blot, Southern blot, and battery separator.

Membrane Technology Overview

Microseparation: process of dividing a homogeneous liquid or gas stream into separate components. Ingredients can be recovered for study for further separation or filtration.

Microfiltration: process of removing minute solid or gelatinous particles from a liquid or gaseous stream through the use of a porous membrane medium. Generally involves membranes in pore sizes ranging from 0.03-5 um.

Phase Inversion Process at American Membrane Corporation

To prepare the sheet-form microporous membrane at American Membrane Corporation, we have adapted a unique process termed "phase inversion process." In the process, organic polymers are first dissolved in an appropriate solvent system with or without the additives, cast onto a stainless steel belt with a precise control of thickness, and precipitated to form a porous nascent membrane either through a solvent evaporation or a non-solvent addition process.

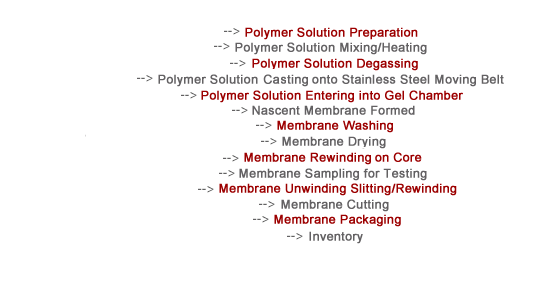

The microporous membrane is then washed with appropriate solvents to remove the residuals present in the membrane and finally dried. The process flow chart shown below outlines the membrane sheet manufacturing procedure:

Binding: the property of substances to have affinity for filter media. Binding can be a desirable characteristic, as in the case of nucleic acid or protein binding on certain microporous transfer membranes, or an undesirable characteristic, as in the case of protein binding during filtration of proteinaceous solutions, sometimes leading to a loss of active ingredients during filtration.

Bubble point: a measurement of the minimal air pressure needed to push liquid (often water) from the largest wetted pore of membrane while forming a steady bubble chain. The larger the pore, the less pressure required to form a stream of bubbles. Bubble point serves as an index of pore size and rates the membrane’s ability to retain particulates.

Cross-flow Filtration: in cross-flow filtration, a feed stream passes tangential to a membrane, establishing a pressure difference across the membrane. This forces some of the feed to flow through the membrane, leaving the remaining feed to continue to flow along the membrane. The use of such tangential flow will prevent thicker particulates from building up a "filter cake."

Dead-end Filtration: in dead-end filtration, all the fluid (i.e., feed) flows through the membrane and all particulates larger than the pore size of the membrane are mainly retained at its surface. In the process, the retained particulates starts to build up a "filter cake" on the surface of the membrane which has an impact on the efficiency of the process.

Depth Filters: usually characterized as those which retain particulates on the surface and within the filter matrix. All conventional fibrous filters are depth filters and are characterized by exhibiting loading capacity.

DOP Test: a measurement of the efficiency of a membrane of the production of ultrapure air based on the 0.3 um Dioctyphthalate aerosol particles passing through a membrane at a predetermined flow.

Downstream Side: the filtrate side of the membrane.

Filtrate: the fluid that has passed through the membrane.

Flow Rate: a measurement of the volume fluid (e.g., water) that passes through a membrane, given a unit of time, surface area, and pressure.

Hydrophilicity: an affinity for water. Hydrophilic membranes generally have specific surface chemistries allowing them to be wetted by water. Hydrophilic membranes can screen either liquid or gases.

Hydrophobicity: referred to be a repulsion for water. Hydrophobic membranes have little or no tendency to absorb water so that a droplet remains on the membrane surface. The degree of repellency generally depends upon filter pore size and inherent polymeric properties of the membrane material. Hydrophobic membranes transmit gas and are often used for venting.

Membrane Filters: generally described as surface filters because the filter matrix acts as a screen and retains particulates almost exclusively on the membrane’s surface.

Microfiltration: a method of removing contaminants from fluids or gases by passing through a microporous membrane in a pore size range from 0.1 um to 10 um. Two techniques are generally used in microfiltration: dead-end filtration and cross-flow filtration. Microfiltration is widely used in production and analytical applications including filtration of particulates from fluids and gases for different industries such as production of pure water, clarification and sterile filtration, waste water treatment, etc...

Molecular Weight Cut Off (MWCO): lowest molecular weight solute that is 90% retained by the membrane. For rapid filtration where some sample loss is acceptable, a membrane having a MWCO the same as the molecular weight of the solute can be used. When loss of material of interest is undesirable, the membrane MWCO should be less than the molecular weight of the compound.

Nominal Rating: a measurement of the smallest particulate a membrane can retain with greater than 90% efficiency. Ratings can differ according to challenging conditions.

Northern Blot: the method by which RNA is fractionated electrophoretically on an Agarose gel, transferred to a membrane filter and probed with radiolabelled DNA or RNA.

Prefiltration: the life of a membrane can be extended by placing a prefiltration stage upstream to the membrane. The prefilter typically is a media that has a high loading capacity. The total particulate load challenging the membrane is considerably reduced thus allowing the membrane to operate more efficiently.

Throughput: a practical term describing the lifespan of membrane, i.e., the total volume of a specific fluid that passes through the membrane before the membrane has to be replaced. This term is interchangeable with dirt holding or loading capacity.

Upstream Side: the feed side of the membrane.

Water Breakthrough: a measurement of the amount of pressure needed to push water through the largest pore of a dry hydrophobic membrane. The larger the pore size, the less pressure required to let water pass.

Western Blot: the process by which proteins are fractionated electrophoretically in a polyacrylamide gel, transferred by active blotting to a membrane filter and probed.

Our extensive knowledge of membrane is always available to you through our Technical Services department. By purchasing from us, you are assured of consistency and reliability across all of our membranes. Our customer support specialists are available to work closely with you during the sampling process. To request a sample of our membrane products, please send an email letting us know of your specific filtration needs. Our technical specialists provide one-on-one technical support for every phase of your filtration project. At American Membrane Corporation, we also develop proprietary membrane or membrane products on a contractual or OEM basis for your special customized requirements.

The following information will help you select our best microporous membranes suitable for your applications. As always, when selecting filtration membranes, there are three key steps to consider:

● Clearly define your application requirements

● Choose a compatible membrane

● Select the most effective and efficient pore size